Dit is de Engelstalige versie. Voor de Nederlandstalige versie, klik hier.

Explanation ISO System of limits and fits:

1. Introduction

2. Limits

3. Fits

4. Glossary

| HOLES | A to E | F, G, H | j, js | K to R | S to ZC |

| shafts | a to e | f, g, h | j, js | k to s | t to zc |

Online calculator

| largest and smallest limits in μm for holes, tolerance grade A to E | |||||||||||||||||||||

| nominal size in mm | A | B | C | D | E | ||||||||||||||||

| above | to | 9 | 11 | 8 | 9 | 11 | 8 | 9 | 11 | 6 | 7 | 8 | 9 | 10 | 11 | 5 | 6 | 7 | 8 | 9 | 10 |

| 1 | 3 | +295 +270 | +330 +270 | +154 +140 | +165 +140 | +200 +140 | +74 +60 | +85 +60 | +120 +60 | +26 +20 | +30 +20 | +34 +20 | +45 +20 | +60 +20 | +80 +20 | +18 +14 | +20 +14 | +24 +14 | +28 +14 | +39 +14 | +54 +14 |

| 3 | 6 | +300 +270 | +345 +270 | +158 +140 | +170 +140 | +215 +140 | +88 +70 | +100 +70 | +145 +70 | +38 +30 | +42 +30 | +48 +30 | +60 +30 | +78 +30 | +105 +30 | +25 +20 | +28 +20 | +32 +20 | +38 +20 | +50 +20 | +68 +20 |

| 6 | 10 | +316 +280 | +370 +280 | +172 +150 | +186 +150 | +240 +150 | +102 +80 | +116 +80 | +170 +80 | +49 +40 | +55 +40 | +62 +40 | +76 +40 | +98 +40 | +130 +40 | +31 +25 | +34 +25 | +40 +25 | +47 +25 | +61 +25 | +83 +25 |

| 10 | 18 | +333 +290 | +400 +290 | +177 +150 | +193 +150 | +260 +150 | +122 +95 | +138 +95 | +205 +95 | +61 +50 | +68 +50 | +77 +50 | +93 +50 | +120 +50 | +160 +50 | +40 +32 | +43 +32 | +50 +32 | +59 +32 | +75 +32 | +102 +32 |

| 18 | 30 | +352 +300 | +430 +300 | +193 +160 | +212 +160 | +290 +160 | +143 +110 | +162 +110 | +240 +110 | +78 +65 | +86 +65 | +98 +65 | +117 +65 | +149 +65 | +195 +65 | +49 +40 | +53 +40 | +61 +40 | +73 +40 | +92 +40 | +124 +40 |

| 30 | 40 | +372 +310 | +470 +310 | +209 +170 | +232 +170 | +330 +170 | +159 +120 | +182 +120 | +280 +120 | +96 +80 | +105 +80 | +119 +80 | +142 +80 | +180 +80 | +240 +80 | +61 +50 | +66 +50 | +75 +50 | +89 +50 | +112 +50 | +150 +50 |

| 40 | 50 | +382 +320 | +480 +320 | +219 +180 | +242 +180 | +340 +180 | +169 +130 | +192 +130 | +290 +130 | ||||||||||||

| 50 | 65 | +414 +340 | +530 +340 | +236 +264 | +264 +190 | +380 +190 | +186 +140 | +214 +140 | +330 +140 | +119 +100 | +130 +100 | +146 +100 | +174 +100 | +220 +100 | +290 +100 | +73 +60 | +79 +60 | +90 +60 | +106 +60 | +134 +60 | +180 +60 |

| 65 | 80 | +434 +360 | +550 +360 | +246 +200 | +174 +200 | +390 +200 | +196 +150 | +224 +150 | +340 +150 | ||||||||||||

| 80 | 100 | +467 +380 | +600 +380 | +274 +220 | +307 +220 | +440 +220 | +224 +170 | +257 +170 | +390 +170 | +142 +120 | +155 +120 | +174 +120 | +207 +120 | +260 +120 | +340 +120 | +87 +72 | +94 +72 | +107 +72 | +126 +72 | +159 +72 | +212 +72 |

| 100 | 120 | +497 +410 | +630 +410 | +294 +240 | +327 +240 | +460 +240 | +234 +180 | +267 +180 | +400 +180 | ||||||||||||

| 120 | 140 | +560 +460 | +710 +460 | +323 +260 | +360 +260 | +510 +260 | +263 +200 | +300 +200 | +450 +200 | +170 +145 | +185 +145 | +208 +145 | +245 +145 | +305 +145 | +395 +145 | +103 +85 | +110 +85 | +125 +85 | +148 +85 | +185 +85 | +245 +85 |

| 140 | 160 | +620 +520 | +770 +520 | +343 +280 | +380 +280 | +530 +280 | +273 +210 | +310 +210 | +460 +210 | ||||||||||||

| 160 | 180 | +680 +580 | +830 +580 | +373 +310 | +410 +310 | +560 +310 | +293 +230 | +330 +230 | +480 +230 | ||||||||||||

| 180 | 200 | +775 +660 | +950 +660 | +412 +340 | +455 +340 | +630 +340 | +312 +240 | +355 +240 | +530 +240 | +199 +170 | +216 +170 | +242 +170 | +285 +170 | +355 +170 | +460 +170 | +120 +100 | +129 +100 | +146 +100 | +172 +100 | +215 +100 | +285 +100 |

| 200 | 225 | +855 +740 | +1030 +740 | +452 +380 | +495 +380 | +670 +380 | +332 +260 | +375 +260 | +550 +260 | ||||||||||||

| 225 | 250 | +935 +820 | +1110 +820 | +492 +420 | +535 +420 | +710 +420 | +352 +280 | +395 +280 | +570 +280 | ||||||||||||

| 250 | 280 | +1050 +920 | +1240 +920 | +561 +480 | +610 +480 | +800 +480 | +381 +300 | +430 +300 | +620 +300 | +222 +190 | +242 +190 | +271 +190 | +320 +190 | +400 +190 | +510 +190 | +133 +110 | +142 +110 | +162 +110 | +191 +110 | +240 +110 | +320 +110 |

| 280 | 315 | +1180 +1050 | +1370 +1050 | +621 +540 | +670 +540 | +860 +540 | +411 +330 | +460 +330 | +650 +330 | ||||||||||||

| 315 | 355 | +1340 +1200 | +1560 +1300 | +689 +600 | +740 +600 | +960 +600 | +449 +360 | +500 +360 | +720 +360 | +246 ++210 | +267 +210 | +299 +210 | +350 +210 | +440 +210 | +570 +210 | +150 +125 | +161 +125 | +182 +125 | +214 +125 | +256 +125 | +355 +125 |

| 355 | 400 | +1490 +1350 | +1710 +1350 | +769 +680 | +820 +680 | +1040 +680 | +489 +400 | +540 +400 | +760 +400 | ||||||||||||

| 400 | 450 | +1655 +1500 | +1900 +1500 | +857 +760 | +915 +760 | +1160 +760 | +537 +440 | +595 +440 | +840 +440 | +270 +230 | +293 +230 | +327 +230 | +385 +230 | +480 +230 | +630 +230 | +162 +135 | +175 +135 | +198 +135 | +232 +135 | +290 +135 | +385 +135 |

| 450 | 500 | +1805 +1650 | +2050 +1650 | +937 +840 | +995 +840 | +1240 +840 | +577 +480 | +635 +480 | +880 +480 | ||||||||||||

| Disclaimer: no rights can be derived from this information. Use of this information is at your own risk. | |||||||||||||||||||||

| Is the tolerance you are looking for not listed? This online calculator calculates all limit deviations. | |||||||||||||||||||||

© Mark Nauta

| largest and smallest limits in μm for holes, tolerance grade F to H | |||||||||||||||||||||||||

| nominal size in mm | F | G | H | ||||||||||||||||||||||

| above | to | 5 | 6 | 7 | 8 | 9 | 5 | 6 | 7 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | 3 | +10 +6 | +12 +6 | +16 +6 | +20 +6 | +31 +6 | +6 +2 | +8 +2 | +12 +2 | +0.8 0 | +1.2 0 | +2 0 | +3 0 | +4 0 | +6 0 | +10 0 | +14 0 | +25 0 | +40 0 | +60 0 | +100 0 | +140 0 | +250 0 | +400 0 | +600 0 |

| 3 | 6 | +15 +10 | +18 +10 | +22 +10 | +28 +10 | +40 +10 | +9 +4 | +12 +4 | +16 +4 | +1 0 | +1.5 0 | +2.5 0 | +4 0 | +5 0 | +8 0 | +12 0 | +18 0 | +30 0 | +48 0 | +75 0 | +120 0 | +180 0 | +300 0 | +480 0 | +750 0 |

| 6 | 10 | +19 +13 | +22 +13 | +28 +13 | +35 +13 | +49 +13 | +11 +5 | +14 +5 | +20 +5 | +1 0 | +1.5 0 | +2.5 0 | +4 0 | +6 0 | +9 0 | +15 0 | +22 0 | +36 0 | +58 0 | +90 0 | +150 0 | +220 0 | +360 0 | +580 0 | +900 0 |

| 10 | 18 | +24 +16 | +27 +16 | +34 +16 | +43 +16 | +59 +16 | +14 +6 | +17 +6 | +24 +6 | +1.2 0 | +2 0 | +3 0 | +5 0 | +8 0 | +11 0 | +18 0 | +27 0 | +43 0 | +70 0 | +110 0 | +180 0 | +270 0 | +430 0 | +700 0 | +1100 0 |

| 18 | 30 | +29 +20 | +33 +20 | +41 +20 | +53 +20 | +72 +20 | +16 +7 | +20 +7 | +28 +7 | +1.5 0 | +2.5 0 | +4 0 | +6 0 | +9 0 | +13 0 | +21 0 | +33 0 | +52 0 | +84 0 | +130 0 | +210 0 | +330 0 | +520 0 | +840 0 | +1300 0 |

| 30 | 50 | +36 +20 | +41 +25 | +50 +25 | +64 +25 | +87 +25 | +20 +9 | +25 +9 | +34 +9 | +1.5 0 | +2.5 0 | +4 0 | +7 0 | +11 0 | +16 0 | +25 0 | +39 0 | +62 0 | +100 0 | +160 0 | +250 0 | +390 0 | +620 0 | +1000 0 | +1600 0 |

| 50 | 80 | +43 +30 | +49 +30 | +60 +30 | +76 +30 | +104 +30 | +23 +10 | +29 +10 | +40 +10 | +2 0 | +3 0 | +5 0 | +8 0 | +13 0 | +19 0 | +30 0 | +46 0 | +74 0 | +120 0 | +190 0 | +300 0 | +460 0 | +740 0 | +1200 0 | +1900 0 |

| 80 | 120 | +51 +36 | +58 +36 | +71 +36 | +90 +36 | +123 +36 | +27 +12 | +34 +12 | +47 +12 | +2.5 0 | +4 0 | +6 0 | +10 0 | +15 0 | +22 0 | +35 0 | +54 0 | +87 0 | +140 0 | +220 0 | +350 0 | +540 0 | +870 0 | +1400 0 | +2200 0 |

| 120 | 180 | +61 +43 | +68 +43 | +83 +43 | +106 +43 | +143 +43 | +32 +14 | +39 +14 | +54 +14 | +3.5 0 | +5 0 | +8 0 | +12 0 | +18 0 | +25 0 | +40 0 | +63 0 | +100 0 | +160 0 | +250 0 | +400 0 | +630 0 | +1000 0 | +1600 0 | +2500 0 |

| 180 | 250 | +70 +50 | +79 +50 | +96 +50 | +122 +50 | +165 +50 | +35 +15 | +44 +15 | +61 +15 | +4.5 0 | +7 0 | +10 0 | +14 0 | +20 0 | +29 0 | +46 0 | +72 0 | +115 0 | +185 0 | +290 0 | +460 0 | +720 0 | +1150 0 | +1850 0 | +2900 0 |

| 250 | 315 | +79 +56 | +88 +56 | +108 +56 | +137 +56 | +186 +56 | +40 +17 | +49 +17 | +69 +17 | +6 0 | +8 0 | +12 0 | +16 0 | +23 0 | +32 0 | +52 0 | +81 0 | +130 0 | +210 0 | +320 0 | +520 0 | +810 0 | +1300 0 | +2100 0 | +3200 0 |

| 315 | 400 | +87 +62 | +98 +62 | +119 +62 | +151 +62 | +202 +62 | +43 +18 | +54 +18 | +75 +18 | +7 0 | +9 0 | +13 0 | +18 0 | +25 0 | +36 0 | +57 0 | +89 0 | +140 0 | +230 0 | +360 0 | +570 0 | +890 0 | +1400 0 | +2300 0 | +3600 0 |

| 400 | 500 | +95 +68 | +108 +68 | +131 +68 | +165 +68 | +223 +68 | +47 +20 | +60 +20 | +83 +20 | +8 0 | +10 0 | +15 0 | +20 0 | +27 0 | +40 0 | +63 0 | +97 0 | +155 0 | +250 0 | +400 0 | +630 0 | +970 0 | +1550 0 | +2500 0 | +4000 0 |

| Disclaimer: no rights can be derived from this information. Use of this information is at your own risk. | |||||||||||||||||||||||||

| Is the tolerance you are looking for not listed? This online calculator calculates all limit deviations. | |||||||||||||||||||||||||

© Mark Nauta

| largest and smallest limits in μm for holes, tolerance grade j and js | |||||||||||||||||||||

| nominal size in mm | j | js | |||||||||||||||||||

| above | to | 6 | 7 | 8 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | |

| 1 | 3 | +2 -4 | +4 -6 | +6 -8 | +0.4 -0.4 | +0.6 -0.6 | +1 -1 | +1.5 -1.5 | +2 -2 | +3 -3 | +5 -5 | +7 -7 | +12.5 -12.5 | +20 -20 | +30 -30 | +50 -50 | +70 -70 | +125 -125 | +200 -200 | +300 -300 | |

| 3 | 6 | +5 -3 | +6 -6 | +10 -8 | +0.5 -0.5 | +0.75 -0.75 | +1.25 -1.25 | +2 -2 | +2.5 -2.5 | +4 -4 | +6 -6 | +9 -9 | +15 -15 | +24 -24 | +37.5 -37.5 | +60 -60 | +90 -90 | +150 -150 | +240 -240 | +375 -375 | |

| 6 | 10 | +5 -4 | +8 -7 | +12 -10 | +0.5 -0.5 | +0.75 -0.75 | +1.25 -1.25 | +2 -2 | +3 -3 | +4.5 -4.5 | +7.5 -7.5 | +11 -11 | +18 -18 | +29 -29 | +45 -45 | +75 -75 | +110 -110 | +180 -180 | +290 -290 | +450 -450 | |

| 10 | 18 | +6 -5 | +10 -8 | +15 -12 | +0.6 -0.6 | +1 -1 | +1.5 -1.5 | +2.5 -2.5 | +4 -4 | +5.5 -5.5 | +9 -9 | +13.5 -13.5 | +21.5 -21.5 | +35 -35 | +55 -55 | +90 -90 | +135 -135 | +215 -215 | +350 -350 | +550 -550 | |

| 18 | 30 | +8 -5 | +12 -9 | +20 -13 | +0.75 -0.75 | +1.25 -1.25 | +2 -2 | +3 -3 | +4.5 -4.5 | +6.5 -6.5 | +10.5 -10.5 | +16.5 -16.5 | +26 -26 | +42 -42 | +65 -65 | +105 -105 | +165 -165 | +260 -260 | +420 -420 | +650 -650 | |

| 30 | 50 | +10 -6 | +14 -11 | +24 -15 | +0.75 -0.75 | +1.25 -1.25 | +2 -2 | +3.5 -3.5 | +5.5 -5.5 | +8 -8 | +12.5 -12.5 | +19.5 -19.5 | +31 -31 | +50 -50 | +80 -80 | +125 -125 | +195 -195 | +310 -310 | +500 -500 | +800 -800 | |

| 50 | 80 | +13 -6 | +18 -12 | +28 -18 | +1 -1 | +1.5 -1.5 | +2.5 -2.5 | +4 -4 | +6.5 -6.5 | +9.5 -9.5 | +15 -15 | +23 -23 | +37 -37 | +60 -60 | +95 -95 | +150 -150 | +230 -230 | +370 -370 | +600 -600 | +950 -950 | |

| 80 | 120 | +16 -6 | +22 -13 | +34 -20 | +1.25 -1.25 | +2 -2 | +3 -3 | +5 -5 | +7.5 -7.5 | +11 -11 | +17.5 -17.5 | +27 -27 | +43.5 -43.5 | +70 -70 | +110 -110 | +175 -175 | +270 -270 | +435 -435 | +700 -700 | +1100 -1100 | |

| 120 | 180 | +18 -7 | +26 -14 | +41 -22 | +1.75 -1.75 | +2.5 -2.5 | +4 -4 | +6 -6 | +9 -9 | +12.5 -12.5 | +20 -20 | +31.5 -31.5 | +50 -50 | +80 -80 | +125 -125 | +200 -200 | +315 -315 | +500 -500 | +800 -800 | +1250 -1250 | |

| 180 | 250 | +22 -7 | +30 -16 | +47 -25 | +2.25 -2.25 | +3.5 -3.5 | +5 -5 | +7 -7 | +10 -10 | +14.5 -14.5 | +23 -23 | +36 -36 | +57.5 -57.5 | +92.5 -92.5 | +145 -145 | +230 -230 | +360 -360 | +575 -575 | +925 -925 | +1450 -1450 | |

| 250 | 315 | +25 -7 | +36 -16 | +55 -26 | +3 -3 | +4 -4 | +6 -6 | +8 -8 | +11.5 -11.5 | +16 -16 | +26 -26 | +40.5 -40.5 | +65 -65 | +105 -105 | +160 -160 | +260 -260 | +405 -405 | +650 -650 | +1050 -1050 | +1600 -1600 | |

| 315 | 400 | +29 -7 | +39 -18 | +60 -29 | +3.5 -3.5 | +4.5 -4.5 | +6.5 -6.5 | +9 -9 | +12.5 -12.5 | +18 -18 | +28.5 -28.5 | +44.5 -44.5 | +70 -70 | +115 -115 | +180 -180 | +285 -285 | +445 -445 | +700 -700 | +1150 -1150 | +1800 -1800 | |

| 400 | 500 | +33 -7 | +43 -20 | +66 -31 | +4 -4 | +5 -5 | +7.5 -7.5 | +10 -10 | +13.5 -13.5 | +20 -20 | +31.5 -31.5 | +48.5 -48.5 | +77.5 -77.5 | +125 -125 | +200 -200 | +315 -315 | +485 -485 | +775 -775 | +1250 -1250 | +2000 -2000 | |

| Disclaimer: no rights can be derived from this information. Use of this information is at your own risk. | |||||||||||||||||||||

| Is the tolerance you are looking for not listed? This online calculator calculates all limit deviations. | |||||||||||||||||||||

© Mark Nauta

| largest and smallest limits in μm for holes, tolerance grade K to R | |||||||||||||||||||||||||

| nominal size in mm | K | M | N | P | R | ||||||||||||||||||||

| above | to | 5 | 6 | 7 | 8 | 5 | 6 | 7 | 8 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 5 | 6 | 7 | 8 | 9 | 5 | 6 | 7 | 8 |

| 1 | 3 | 0 -4 | 0 -6 | 0 -10 | 0 -14 | -2 -6 | -2 -8 | -2 -12 | - | -4 -8 | -4 -10 | -4 -14 | -4 -18 | -4 -29 | -4 -44 | -4 -64 | -6 -10 | -6 -12 | -6 -16 | -6 -20 | -6 -31 | -10 -14 | -10 -16 | -10 -20 | -10 -24 |

| 3 | 6 | 0 -5 | +2 -6 | +3 -9 | +5 -13 | -3 -8 | -1 -9 | 0 -12 | +2 -16 | -7 -12 | -5 -13 | -4 -16 | -2 -20 | 0 -30 | 0 -48 | 0 -75 | -11 -16 | -9 -17 | -8 -20 | -12 -30 | -12 -42 | -14 -19 | -12 -20 | -11 -23 | -15 -33 |

| 6 | 10 | +1 -5 | +2 -7 | +5 -10 | +6 -16 | -4 -10 | -3 -12 | 0 -15 | +1 -21 | -8 -14 | -7 -16 | -4 -19 | -3 -25 | 0 -36 | 0 -58 | 0 -90 | -13 -19 | -12 -21 | -9 -24 | -15 -37 | -15 -51 | -17 -23 | -16 -25 | -13 -28 | -19 -41 |

| 10 | 18 | +2 -6 | +2 -9 | +6 -12 | +8 -19 | -4 -12 | -4 -15 | 0 -18 | +2 -25 | -9 -17 | -9 -20 | -5 -23 | -3 -30 | 0 -43 | 0 -70 | 0 -110 | -15 -23 | -15 -26 | -11 -29 | -18 -45 | -18 -61 | -20 -28 | -20 -31 | -16 -34 | -23 -50 |

| 18 | 30 | +1 -8 | +2 -11 | +6 -15 | +10 -23 | -5 -14 | -4 -17 | 0 -21 | +4 -29 | -12 -21 | -11 -24 | -7 -28 | -3 -36 | 0 -52 | 0 -84 | 0 130 | -19 -28 | -18 -31 | -14 -35 | -22 -55 | -22 -74 | -25 -34 | -24 -37 | -20 -41 | -28 -61 |

| 30 | 50 | +2 -9 | +3 -13 | +7 -18 | +12 -27 | -5 -16 | -4 -20 | 0 -25 | +5 -34 | -13 -24 | -12 -28 | -8 -33 | -3 -42 | 0 -62 | 0 -100 | 0 -160 | -22 -33 | -21 -37 | -17 -42 | -26 -65 | -26 -88 | -30 -41 | -29 -45 | -25 -50 | -34 -73 |

| 50 | 65 | +3 -10 | +4 -15 | +9 -21 | +14 -32 | -6 -19 | -5 -24 | 0 -30 | +5 -41 | -15 -28 | -14 -33 | -9 -39 | -4 -50 | 0 -74 | 0 -120 | 0 -190 | -27 -40 | -26 -45 | -21 -51 | -32 -78 | -32 -106 | -36 -49 | -35 -54 | -30 -60 | -41 -87 |

| 65 | 80 | -38 -51 | -37 -56 | -32 -62 | -43 -89 | ||||||||||||||||||||

| 80 | 100 | +2 -13 | +4 -18 | +10 -25 | +16 -38 | -8 -23 | -6 -28 | 0 -35 | +6 -48 | -18 -33 | -16 -38 | -10 -45 | -4 -58 | 0 -87 | 0 -140 | 0 -220 | -32 -47 | -30 -52 | -24 -59 | -37 -91 | -37 -124 | -46 -61 | -44 -66 | -38 -73 | -51 -105 |

| 100 | 120 | -49 -64 | -47 -69 | -41 -76 | -54 -108 | ||||||||||||||||||||

| 120 | 140 | +3 -15 | +4 -21 | +12 -28 | +20 -43 | -9 -27 | -8 -33 | 0 -40 | +8 -55 | -21 -39 | -20 -45 | -12 -52 | -4 -67 | 0 -100 | 0 -160 | 0 -250 | -37 -55 | -36 -61 | -28 -68 | -43 -106 | -43 -143 | -57 -75 | -56 -81 | -48 -88 | -63 -126 |

| 140 | 160 | -59 -77 | -58 -83 | -50 -90 | -65 -128 | ||||||||||||||||||||

| 160 | 180 | -62 -80 | -61 -86 | -53 -93 | -68 -131 | ||||||||||||||||||||

| 180 | 200 | +2 -18 | +5 -24 | +13 -33 | +22 -50 | -11 -31 | -8 -37 | 0 -46 | +9 -63 | -25 -45 | -22 -51 | -14 -60 | -5 -77 | 0 -115 | 0 -185 | 0 -290 | -44 -64 | -41 -70 | -33 -79 | -50 -122 | -50 -165 | -71 -91 | -68 -97 | -60 -106 | -77 -149 |

| 200 | 225 | -74 -94 | -71 -100 | -63 -109 | -80 -152 | ||||||||||||||||||||

| 225 | 250 | -78 -98 | -75 -104 | -67 -113 | -84 -156 | ||||||||||||||||||||

| 250 | 280 | +3 -20 | +5 -27 | +16 -36 | +25 -56 | -13 -36 | -9 -41 | 0 -52 | +9 -72 | -27 -50 | -25 -57 | -14 -66 | -5 -86 | 0 -130 | 0 -210 | 0 -320 | -49 -72 | -47 -79 | -36 -88 | -56 -137 | -56 -186 | -87 -110 | -85 -117 | -74 -126 | -94 -175 |

| 280 | 315 | -91 -114 | -89 -121 | -78 -130 | -98 -179 | ||||||||||||||||||||

| 315 | 355 | +3 -22 | +7 -29 | +17 -40 | +28 -61 | -14 -39 | -10 -46 | 0 -57 | +11 -78 | -30 -55 | -26 -62 | -16 -73 | -5 -94 | 0 -140 | 0 -230 | 0 -360 | -55 -80 | -51 -87 | -41 -98 | -62 -151 | -62 -202 | -101 -126 | -97 -133 | -87 -144 | -108 -197 |

| 355 | 400 | -107 -132 | -103 -139 | -93 -150 | -114 -203 | ||||||||||||||||||||

| 400 | 450 | +2 -25 | +8 -32 | +18 -45 | +29 -68 | -16 -43 | -10 -50 | 0 -63 | +11 -86 | -33 -60 | -27 -67 | -17 -80 | -6 -103 | 0 -155 | 0 -250 | 0 -400 | -61 -88 | -55 -95 | -45 -108 | -68 -165 | -68 -223 | -119 -146 | -113 -153 | -103 -166 | -126 -223 |

| 450 | 500 | -125 -152 | -119 -159 | -109 -172 | -132 -229 | ||||||||||||||||||||

| Disclaimer: no rights can be derived from this information. Use of this information is at your own risk. | |||||||||||||||||||||||||

| Is the tolerance you are looking for not listed? This online calculator calculates all limit deviations. | |||||||||||||||||||||||||

© Mark Nauta

| largest and smallest limits in μm for holes, tolerance grade S to ZC | |||||||||||||||||||||

| S | T | U | V | X | Y | Z | ZA | ZB | ZC | ||||||||||||

| above | to | 5 | 6 | 7 | 6 | 7 | 6 | 7 | 6 | 7 | 6 | 7 | 7 | 7 | 8 | 7 | 8 | 8 | 9 | 8 | 9 |

| 1 | 3 | -14 -18 | -14 -20 | 14 -24 | - | - | -18 -24 | -18 -28 | - | - | -20 -26 | -20 -30 | - | -26 -36 | -26 -40 | -32 -42 | -32 -46 | -40 -54 | -40 -65 | -60 -74 | -60 -85 |

| 3 | 6 | -18 -23 | -16 -24 | -15 -27 | - | - | -20 -28 | -19 -31 | - | - | -25 -33 | -24 -36 | - | -31 -43 | -35 -53 | -38 -50 | -42 -60 | -50 -68 | -50 -80 | -80 -98 | -80 -110 |

| 6 | 10 | -21 -27 | -20 -29 | -17 -32 | - | - | -25 -34 | -22 -37 | - | - | -31 -40 | -28 -43 | - | -36 -51 | -42 -64 | -46 -61 | -52 -74 | -67 -89 | -67 -103 | -97 -119 | -97 -133 |

| 10 | 14 | -25 -33 | -25 -36 | -21 -39 | - | - | -30 -41 | -26 -44 | - | - | -37 -48 | -33 -51 | - | -43 -61 | -50 -77 | ||||||

| 14 | 18 | -36 -77 | -32 -50 | -42 -53 | -38 -56 | - | -53 -71 | -60 -87 | |||||||||||||

| 18 | 24 | -32 -41 | -31 -44 | -27 -48 | - | - | -37 -50 | -33 -54 | -43 -56 | -39 -60 | -50 -63 | -46 -67 | -55 -76 | -65 -86 | -73 -106 | ||||||

| 24 | 30 | -37 -50 | -33 -54 | -44 -57 | -40 -61 | -51 -64 | -47 -68 | -60 -73 | -56 -77 | -67 -88 | -80 -101 | -88 -121 | |||||||||

| 30 | 40 | -39 -50 | -38 -54 | -34 -59 | -43 -59 | -39 -64 | -55 -71 | -51 -76 | -63 -79 | -59 -84 | -75 -91 | -71 -96 | -85 -110 | -103 -128 | -112 -151 | ||||||

| 40 | 50 | -49 -65 | -45 -70 | -65 -81 | -61 -86 | -76 -92 | -72 -97 | -92 -108 | -88 -113 | -105 -130 | -127 -152 | -136 -175 | |||||||||

| 50 | 65 | -48 -61 | -47 -66 | -42 -72 | -60 -79 | -55 -85 | -81 -100 | -76 -106 | -96 -115 | -91 -121 | -116 -135 | -111 -141 | -133 -163 | -161 -191 | -172 -218 | ||||||

| 65 | 80 | -54 -67 | -53 -72 | -48 -78 | -69 -88 | -64 -94 | -96 -115 | -91 -121 | -114 -133 | -109 -139 | -140 -159 | -135 -165 | -163 -193 | -199 -229 | -210 -256 | ||||||

| 80 | 100 | -66 -81 | -64 -86 | -58 -93 | -84 -106 | -78 -113 | -117 -139 | -111 -146 | -139 -161 | -133 -168 | -171 -193 | -165 -200 | -201 -236 | -245 -280 | -258 -312 | ||||||

| 100 | 120 | -74 -89 | -72 -94 | -66 -101 | -97 -119 | -91 -126 | -137 -159 | -131 -166 | -165 -187 | -159 -194 | -203 -225 | -197 -232 | -241 -276 | -297 -332 | -310 -364 | ||||||

| 120 | 140 | -86 -104 | -85 -110 | -77 -117 | -115 -140 | -107 -147 | -163 -188 | -155 -195 | -195 -220 | -187 -227 | -241 -266 | -233 -273 | -285 -325 | -350 -390 | -365 -428 | ||||||

| 140 | 160 | -94 -112 | -93 -118 | -85 -125 | -127 -152 | -119 -159 | -138 -208 | -175 -215 | -221 -246 | -213 -253 | -273 -298 | -265 -305 | -325 -365 | -400 -440 | -415 -478 | ||||||

| 160 | 180 | -102 -120 | -101 -126 | -93 -133 | -139 -164 | -131 -171 | -203 -228 | -195 -235 | -245 -270 | -237 -277 | -303 -328 | -295 -335 | -365 -405 | -450 -490 | -465 -528 | ||||||

| 180 | 200 | -116 -136 | -113 -142 | -105 -151 | -157 -186 | -149 -195 | -227 -256 | -219 -265 | -275 -304 | -267 -313 | -341 -370 | -333 -379 | -408 -454 | -503 -549 | -520 -592 | ||||||

| 200 | 225 | -124 -144 | -121 -150 | -113 -159 | -171 -200 | -163 -209 | -249 -278 | -241 -287 | -301 -330 | -293 -339 | -376 -405 | -368 -414 | -453 -499 | -558 -604 | -575 -647 | ||||||

| 225 | 250 | -134 -154 | -131 -160 | -123 -169 | -187 -216 | -179 -225 | -275 -304 | -267 -313 | -331 -360 | -323 -369 | -416 -445 | -408 -454 | -503 -549 | -623 -669 | -640 -712 | ||||||

| 250 | 280 | -151 -174 | -149 -181 | -138 -190 | -209 -241 | -198 -250 | -306 -338 | -295 -347 | -376 -408 | -365 -417 | -466 -498 | -455 -507 | -560 -612 | -690 -742 | -710 -791 | ||||||

| 280 | 315 | -163 -186 | -161 -193 | -150 -202 | -231 -263 | -220 -272 | -341 -373 | -330 -382 | -416 -448 | -405 -457 | -516 -548 | -505 -557 | -630 -682 | -770 -822 | -790 -871 | ||||||

| 315 | 355 | -183 -208 | -179 -215 | -169 -226 | -257 -293 | -247 -304 | -379 -415 | -369 -426 | -464 -500 | -454 -511 | -579 -615 | -569 -626 | -709 -766 | -879 -936 | -900 -989 | ||||||

| 355 | 400 | -201 -226 | -197 -233 | -187 -244 | -283 -319 | -273 -330 | -424 -460 | -414 -471 | -519 -555 | -509 -566 | -649 -685 | -639 -696 | -799 -856 | -979 -1036 | -1000 -1089 | ||||||

| 400 | 450 | -225 -252 | -219 -259 | -209 -272 | -317 -357 | -307 -370 | -477 -517 | -467 -530 | -582 -622 | -572 -635 | -727 -767 | -717 -780 | -897 -960 | -1077 -1140 | -1100 -1197 | ||||||

| 450 | 500 | -245 -272 | -239 -279 | -229 -292 | -347 -387 | -337 -400 | -527 -567 | -517 -580 | -647 -687 | -637 -700 | -807 -847 | -797 -860 | -977 -1040 | -1227 -1290 | -1250 -1347 | ||||||

| Disclaimer: no rights can be derived from this information. Use of this information is at your own risk. | |||||||||||||||||||||

| Is the tolerance you are looking for not listed? This online calculator calculates all limit deviations. | |||||||||||||||||||||

© Mark Nauta

| largest and smallest limits in μm for shafs, tolerance grade a to e | |||||||||||||||||||||

| nominal size in mm | a | b | c | d | e | ||||||||||||||||

| above | to | 9 | 11 | 8 | 9 | 11 | 8 | 9 | 11 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 5 | 6 | 7 | 8 | 9 |

| 1 | 3 | -270 -295 | -270 -330 | -140 -154 | -140 -165 | -140 -200 | -60 -74 | -60 -85 | -60 -120 | -20 -24 | -20 -26 | -20 -30 | -20 34- | -20 -45 | -20 -60 | -20 -80 | -14 -18 | -14 -20 | -14 -24 | -14 -28 | -14 -39 |

| 3 | 6 | -270 -300 | -270 -345 | -140 -158 | -140 -170 | -140 -215 | -70 -88 | -70 -100 | -70 -145 | -30 -35 | -30 -38 | -30 -42 | -30 -48 | -30 -60 | -30 -78 | -30 -105 | -20 -25 | -20 -28 | -20 -32 | -20 -38 | -20 -50 |

| 6 | 10 | -280 -316 | -280 -370 | -150 -172 | -150 -186 | -150 -240 | -80 -102 | -80 -116 | -80 -170 | -40 -46 | -40 -49 | -40 -55 | -40 -62 | -40 -76 | -40 -98 | -40 -130 | -25 -31 | -25 -34 | -25 -40 | -25 -47 | -25 -61 |

| 10 | 18 | -290 -333 | -290 -400 | -150 -177 | -150 -193 | -150 -260 | -95 -122 | -95 -138 | -95 -205 | -50 -58 | -50 -61 | -50 -68 | -50 -77 | -50 -93 | -50 -120 | -50 -160 | -32 -40 | -32 -43 | -32 -50 | -32 -59 | -32 -75 |

| 18 | 30 | -300 -352 | -300 -430 | -160 -193 | -160 -212 | -160 -290 | -110 -143 | -110 -162 | -110 -240 | -65 -74 | -65 -78 | -65 -86 | -65 -98 | -65 -117 | -65 -149 | -65 -195 | -40 -49 | -40 -53 | -40 -61 | -40 -73 | -40 -92 |

| 30 | 40 | -310 -372 | -310 -470 | -170 -209 | -170 -232 | -170 -330 | -120 -159 | -120 -182 | -120 -280 | -80 -91 | -80 -96 | -80 -105 | -80 -119 | -80 -142 | -80 -180 | -80 -240 | -50 -61 | -50 -66 | -50 -75 | -50 -89 | -50 -112 |

| 40 | 50 | -320 -382 | -320 -480 | -180 -219 | -180 -242 | -180 -340 | -130 -169 | -130 -192 | -130 -290 | ||||||||||||

| 50 | 65 | -340 -414 | -340 -530 | -190 -236 | -190 -264 | -190 -380 | -140 -186 | -140 -214 | -140 -330 | -100 -113 | -100 -119 | -100 -130 | -100 -146 | -100 -174 | -100 -220 | -100 -290 | -60 -73 | -60 -79 | -60 -90 | -60 -106 | -60 -134 |

| 65 | 80 | -360 -434 | -360 -550 | -200 -246 | -200 -274 | -200 -390 | -150 -196 | -150 -224 | -150 -340 | ||||||||||||

| 80 | 100 | -380 -467 | -380 -600 | -220 -274 | -220 -307 | -220 -440 | -170 -224 | -170 -257 | -170 -390 | -120 -135 | -120 -142 | -120 -155 | -120 -174 | -120 -207 | -120 -260 | -120 -340 | -72 -87 | -72 -94 | -72 -107 | -72 -126 | -72 -159 |

| 100 | 120 | -410 -497 | -410 -630 | -240 -294 | -240 -327 | -240 -460 | -180 -234 | -180 -267 | -180 -400 | ||||||||||||

| 120 | 140 | -460 -560 | -460 -710 | -260 -323 | -260 -360 | -260 -510 | -200 -263 | -200 -300 | -200 -450 | -145 -163 | -145 -170 | -145 -185 | -145 -208 | -145 -245 | -145 -305 | -145 -395 | -85 -103 | -85 -110 | -85 -125 | -85 -148 | -85 -185 |

| 140 | 160 | -520 -620 | -520 -770 | -280 -343 | -280 -380 | -280 -530 | -210 -273 | -210 -310 | -210 -460 | ||||||||||||

| 160 | 180 | -580 -680 | -580 -830 | -310 -373 | -310 -410 | -310 -560 | -230 -293 | -230 -330 | -230 -480 | ||||||||||||

| 180 | 200 | -660 -775 | -660 -950 | -340 -412 | -340 -455 | -340 -630 | -240 -312 | -240 -355 | -240 -530 | -170 -190 | -170 -199 | -170 -216 | -170 -242 | -170 -285 | -170 -355 | -170 -460 | -100 -120 | -100 -129 | -100 -146 | -100 -172 | -100 -215 |

| 200 | 225 | -740 -855 | -740 -1030 | -380 -452 | -380 -495 | -380 -670 | -260 -332 | -260 -375 | -260 -550 | ||||||||||||

| 225 | 250 | -820 -935 | -820 -1110 | -420 -492 | -420 -535 | -420 -710 | -280 -352 | -280 -395 | -280 -570 | ||||||||||||

| 250 | 280 | -920 -1050 | -920 -1240 | -480 -561 | -480 -610 | -480 -800 | -300 -381 | -300 -430 | -300 -620 | -190 -213 | -190 -222 | -190 -242 | -190 -271 | -190 -320 | -190 -400 | -190 -510 | -110 -133 | -110 -142 | -110 -162 | -110 -191 | -110 -240 |

| 280 | 315 | -1050 -1180 | -1050 -1370 | -540 -621 | -540 -670 | -540 -860 | -330 -411 | -330 -460 | -330 -650 | ||||||||||||

| 315 | 355 | -1200 -1340 | -1200 -1560 | -600 -689 | -600 -740 | -600 -960 | -360 -449 | -360 -500 | -360 -720 | -210 -235 | -210 -246 | -210 -267 | -210 -299 | -210 -350 | -210 -440 | -210 -570 | -125 -150 | -125 -161 | -125 -182 | -125 -214 | -125 -265 |

| 355 | 400 | -1350 -1490 | -1350 -1710 | -680 -769 | -680 -820 | -680 -1040 | -400 -489 | -400 -540 | -400 -760 | ||||||||||||

| 400 | 450 | -1500 -1655 | -1500 -1900 | -760 -857 | -760 -915 | -760 -1160 | -440 -537 | -440 -595 | -440 -840 | -230 -257 | -230 -270 | -230 -293 | -230 -327 | -230 -385 | -230 -480 | -230 -630 | -135 -162 | -135 -175 | -135 -198 | -135 -232 | -135 -290 |

| 450 | 500 | -1650 -1805 | -1650 -2050 | -840 -937 | -840 -995 | -840 -1240 | -480 -577 | -480 -635 | -480 -880 | ||||||||||||

| Disclaimer: no rights can be derived from this information. Use of this information is at your own risk. | |||||||||||||||||||||

| Is the tolerance you are looking for not listed? This online calculator calculates all limit deviations. | |||||||||||||||||||||

© Mark Nauta

| largest and smallest limits in μm for shafts, tolerance grade f to h | |||||||||||||||||||||||||||

| nominal size in mm | f | g | h | ||||||||||||||||||||||||

| above | to | 4 | 5 | 6 | 7 | 8 | 9 | 4 | 5 | 6 | 7 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | 3 | -6 -9 | -6 -10 | -6 -12 | -6 -16 | -6 -20 | -6 -31 | -2 -5 | -2 -6 | -2 -8 | -2 -12 | 0 -0.8 | 0 -1.2 | 0 -2 | 0 -3 | 0 -4 | 0 -6 | 0 -10 | 0 -14 | 0 -25 | 0 -40 | 0 -60 | 0 -100 | 0 -140 | 0 -250 | 0 -400 | 0 -600 |

| 3 | 6 | -10 -14 | -10 -15 | -10 -18 | -10 -22 | -10 -28 | -10 -40 | -4 -8 | -4 -9 | -4 -12 | -4 -16 | 0 -1 | 0 -1.5 | 0 -2.5 | 0 -4 | 0 -5 | 0 -8 | 0 -12 | 0 -18 | 0 -30 | 0 -48 | 0 -75 | 0 -120 | 0 -180 | 0 -300 | 0 -480 | 0 -750 |

| 6 | 10 | -13 -17 | -13 -19 | -13 -22 | -13 -28 | -13 -35 | -13 -49 | -5 -9 | -5 -11 | -5 -14 | -5 -20 | 0 -1 | 0 -1.5 | 0 -2.5 | 0 -4 | 0 -6 | 0 -9 | 0 -15 | 0 -22 | 0 -36 | 0 -58 | 0 -90 | 0 -150 | 0 -220 | 0 -360 | 0 -580 | 0 -900 |

| 10 | 18 | -16 -21 | -16 -24 | -16 -27 | -16 -34 | -16 -43 | -16 -59 | -6 -11 | -6 -14 | -6 -17 | -6 -24 | 0 -1.2 | 0 -2 | 0 -3 | 0 -5 | 0 -8 | 0 -11 | 0 -18 | 0 -27 | 0 -43 | 0 -70 | 0 -110 | 0 -180 | 0 -270 | 0 -430 | 0 -700 | 0 -1100 |

| 18 | 30 | -20 -26 | -20 -29 | -20 -33 | -20 -41 | -20 -53 | -20 -72 | -7 -13 | -7 -16 | -7 -20 | -7 -28 | 0 -1.5 | 0 -2.5 | 0 -4 | 0 -6 | 0 -9 | 0 -13 | 0 -21 | 0 -33 | 0 -52 | 0 -84 | 0 -130 | 0 -210 | 0 -330 | 0 -520 | 0 -840 | 0 -1300 |

| 30 | 50 | -25 -32 | -25 -36 | -25 -41 | -25 -50 | -25 -64 | -25 -87 | -9 -16 | -9 -20 | -9 -25 | -9 -34 | 0 -1.5 | 0 -2.5 | 0 -4 | 0 -7 | 0 -11 | 0 -16 | 0 -25 | 0 -39 | 0 -62 | 0 -100 | 0 -160 | 0 -250 | 0 -390 | 0 -620 | 0 -1000 | 0 -1600 |

| 50 | 80 | -30 -38 | -30 -43 | -30 -49 | -30 -60 | -30 -76 | -30 -104 | -10 -18 | -10 -23 | -10 -29 | -10 -40 | 0 -2 | 0 -3 | 0 -5 | 0 -8 | 0 -13 | 0 -19 | 0 -30 | 0 -46 | 0 -74 | 0 -120 | 0 -190 | 0 -300 | 0 -460 | 0 -740 | 0 -1200 | 0 -1900 |

| 80 | 120 | -36 -46 | -36 -51 | -36 -58 | -36 -71 | -36 -90 | -36 -123 | -12 -22 | -12 -27 | -12 -34 | -12 -47 | 0 -2.5 | 0 -4 | 0 -6 | 0 -10 | 0 -15 | 0 -22 | 0 -35 | 0 -54 | 0 -87 | 0 -140 | 0 -220 | 0 -350 | 0 -540 | 0 -870 | 0 -1400 | 0 -2200 |

| 120 | 180 | -43 -55 | -43 -61 | -43 -68 | -43 -83 | -43 -106 | -43 -143 | -14 -26 | -14 -32 | -14 -39 | -14 -54 | 0 -3.5 | 0 -5 | 0 -8 | 0 -12 | 0 -18 | 0 -25 | 0 -40 | 0 -63 | 0 -100 | 0 -160 | 0 -250 | 0 -400 | 0 -630 | 0 -1000 | 0 -1600 | 0 -2500 |

| 180 | 250 | -50 -64 | -50 -70 | -50 -79 | -50 -96 | -50 -122 | -50 -165 | -15 -29 | -15 -35 | -15 -44 | -15 -61 | 0 -4.5 | 0 -7 | 0 -10 | 0 -14 | 0 -20 | 0 -29 | 0 -46 | 0 -72 | 0 -115 | 0 -185 | 0 -290 | 0 -460 | 0 -720 | 0 -1150 | 0 -1850 | 0 -2900 |

| 250 | 315 | -56 -72 | -56 -79 | -56 -88 | -56 -108 | -56 -137 | -56 -186 | -17 -33 | -17 -40 | -17 -49 | -17 -69 | 0 -6 | 0 -8 | 0 -12 | 0 -16 | 0 -23 | 0 -32 | 0 -52 | 0 -81 | 0 -130 | 0 -210 | 0 -320 | 0 -520 | 0 -810 | 0 -1300 | 0 -2100 | 0 -3200 |

| 315 | 400 | -62 -80 | -62 -87 | -62 -98 | -62 -119 | -62 -151 | -62 -202 | -18 -36 | -18 -43 | -18 -54 | -18 -75 | 0 -7 | 0 -9 | 0 -13 | 0 -18 | 0 -25 | 0 -36 | 0 -57 | 0 -89 | 0 -140 | 0 -230 | 0 -360 | 0 -570 | 0 -890 | 0 -1400 | 0 -2300 | 0 -3600 |

| 400 | 500 | -68 -88 | -68 -95 | -68 -108 | -68 -131 | -68 -165 | -68 -223 | -20 -40 | -20 -47 | -20 -60 | -20 -83 | 0 -8 | 0 -10 | 0 -15 | 0 -20 | 0 -27 | 0 -40 | 0 -63 | 0 -97 | 0 -155 | 0 -250 | 0 -400 | 0 -630 | 0 -970 | 0 -1550 | 0 -2500 | 0 -4000 |

| Disclaimer: no rights can be derived from this information. Use of this information is at your own risk. | |||||||||||||||||||||||||||

| Is the tolerance you are looking for not listed? This online calculator calculates all limit deviations. | |||||||||||||||||||||||||||

© Mark Nauta

| largest and smallest limits in μm for shafs, tolerance grade j and js | |||||||||||||||||||||

| nominal size in mm | j | js | |||||||||||||||||||

| above | to | 5 | 6 | 7 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | |

| 1 | 3 | +2 -2 | +4 -2 | +6 -4 | +0.4 -0.4 | +0.6 -0.6 | +1 -1 | +1.5 -1.5 | +2 -2 | +3 -3 | +5 -5 | +7 -7 | +12.5 -12.5 | +20 -20 | +30 -30 | +50 -50 | +70 -70 | +125 -125 | +200 -200 | +300 -300 | |

| 3 | 6 | +3 -2 | +6 -2 | +8 -4 | +0.5 -0.5 | +0.75 -0.75 | +1.25 -1.25 | +2 -2 | +2.5 -2.5 | +4 -4 | +6 -6 | +9 -9 | +15 -15 | +24 -24 | +37.5 -37.5 | +60 -60 | +90 -90 | +150 -150 | +240 -240 | +375 -375 | |

| 6 | 10 | +4 -2 | +7 -2 | +10 -5 | +0.5 -0.5 | +0.75 -0.75 | +1.25 -1.25 | +2 -2 | +3 -3 | +4.5 -4.5 | +7.5 -7.5 | +11 -11 | +18 -18 | +29 -29 | +45 -45 | +75 -75 | +110 -110 | +180 -180 | +290 -290 | +450 -450 | |

| 10 | 18 | +5 -3 | +8 -3 | +12 -6 | +0.6 -0.6 | +1 -1 | +1.5 -1.5 | +2.5 -2.5 | +4 -4 | +5.5 -5.5 | +9 -9 | +13.5 -13.5 | +21.5 -21.5 | +35 -35 | +55 -55 | +90 -90 | +135 -135 | +215 -215 | +350 -350 | +550 -550 | |

| 18 | 30 | +5 -4 | +9 -4 | +13 -8 | +0.75 -0.75 | +1.25 -1.25 | +2 -2 | +3 -3 | +4.5 -4.5 | +6.5 -6.5 | +10.5 -10.5 | +16.5 -16.5 | +26 -26 | +42 -42 | +65 -65 | +105 -105 | +165 -165 | +260 -260 | +420 -420 | +650 -650 | |

| 30 | 50 | +6 -5 | +11 -5 | +15 -10 | +0.75 -0.75 | +1.25 -1.25 | +2 -2 | +3.5 -3.5 | +5.5 -5.5 | +8 -8 | +12.5 -12.5 | +19.5 -19.5 | +31 -31 | +50 -50 | +80 -80 | +125 -125 | +195 -195 | +310 -310 | +500 -500 | +800 -800 | |

| 50 | 80 | +6 -7 | +12 -7 | +18 -12 | +1 -1 | +1.5 -1.5 | +2.5 -2.5 | +4 -4 | +6.5 -6.5 | +9.5 -9.5 | +15 -15 | +23 -23 | +37 -37 | +60 -60 | +95 -95 | +150 -150 | +230 -230 | +370 -370 | +600 -600 | +950 -950 | |

| 80 | 120 | +6 -9 | +13 -9 | +20 -15 | +1.25 -1.25 | +2 -2 | +3 -3 | +5 -5 | +7.5 -7.5 | +11 -11 | +17.5 -17.5 | +27 -27 | +43.5 -43.5 | +70 -70 | +110 -110 | +175 -175 | +270 -270 | +435 -435 | +700 -700 | +1100 -1100 | |

| 120 | 180 | +7 -11 | +14 -11 | +22 -18 | +1.75 -1.75 | +2.5 -2.5 | +4 -4 | +6 -6 | +9 -9 | +12.5 -12.5 | +20 -20 | +31.5 -31.5 | +50 -50 | +80 -80 | +125 -125 | +200 -200 | +315 -315 | +500 -500 | +800 -800 | +1250 -1250 | |

| 180 | 250 | +7 -13 | +16 -13 | +25 -21 | +2.25 -2.25 | +3.5 -3.5 | +5 -5 | +7 -7 | +10 -10 | +14.5 -14.5 | +23 -23 | +36 -36 | +57.5 -57.5 | +92.5 -92.5 | +145 -145 | +230 -230 | +360 -360 | +575 -575 | +925 -925 | +1450 -1450 | |

| 250 | 315 | +7 -16 | +16 -16 | +26 -26 | +3 -3 | +4 -4 | +6 -6 | +8 -8 | +11.5 -11.5 | +16 -16 | +26 -26 | +40.5 -40.5 | +65 -65 | +105 -105 | +160 -160 | +260 -260 | +405 -405 | +650 -650 | +1050 -1050 | +1600 -1600 | |

| 315 | 400 | +7 -18 | +18 -18 | +29 -28 | +3.5 -3.5 | +4.5 -4.5 | +6.5 -6.5 | +9 -9 | +12.5 -12.5 | +18 -18 | +28.5 -28.5 | +44.5 -44.5 | +70 -70 | +115 -115 | +180 -180 | +285 -285 | +445 -445 | +700 -700 | +1150 -1150 | +1800 -1800 | |

| 400 | 500 | +7 -20 | +20 -20 | +31 -32 | +4 -4 | +5 -5 | +7.5 -7.5 | +10 -10 | +13.5 -13.5 | +20 -20 | +31.5 -31.5 | +48.5 -48.5 | +77.5 -77.5 | +125 -125 | +200 -200 | +315 -315 | +485 -485 | +775 -775 | +1250 -1250 | +2000 -2000 | |

| Disclaimer: no rights can be derived from this information. Use of this information is at your own risk. | |||||||||||||||||||||

| Is the tolerance you are looking for not listed? This online calculator calculates all limit deviations. | |||||||||||||||||||||

© Mark Nauta

| largest and smallest limits in μm for shafts, tolerance grade k to s | |||||||||||||||||||||||||

| nominal size in mm | k | m | n | p | r | s | |||||||||||||||||||

| above | to | 4 | 5 | 6 | 7 | 4 | 5 | 6 | 7 | 4 | 5 | 6 | 7 | 4 | 5 | 6 | 7 | 4 | 5 | 6 | 7 | 4 | 5 | 6 | 7 |

| 1 | 3 | +3 0 | +4 0 | +6 0 | +10 0 | +5 +2 | +6 +2 | +8 +2 | - | +7 +4 | +8 +4 | +10 +4 | +14 +4 | +9 +6 | +10 +6 | +12 +6 | +16 +6 | +13 +10 | +14 +10 | +16 +10 | +20 +10 | +17 +14 | +18 +14 | +20 +14 | +24 +14 |

| 3 | 6 | +5 +1 | +6 +1 | +9 +1 | +13 +1 | +8 +4 | +9 +4 | +12 +4 | +16 +4 | +12 +8 | +13 +8 | +16 +8 | +20 +8 | +16 +12 | +17 +12 | +20 +12 | +24 +12 | +19 +15 | +20 +15 | +23 +15 | +27 +15 | +23 +19 | +24 +19 | +27 +19 | +31 +19 |

| 6 | 10 | +5 +1 | +7 +1 | +10 +1 | +16 +1 | +10 +6 | +12 +6 | +15 +6 | +21 +6 | +14 +10 | +16 +10 | +19 +10 | +25 +10 | +19 +15 | +21 +15 | +24 +15 | +30 +15 | +23 +19 | +25 +19 | +28 +19 | +34 +19 | +27 +23 | +29 +23 | +32 +23 | +38 +23 |

| 10 | 18 | +6 +1 | +9 +1 | +12 +1 | +19 +1 | +12 +7 | +15 +7 | +18 +7 | +25 +7 | +17 +12 | +20 +12 | +23 +12 | +30 +12 | +23 +18 | +26 +18 | +29 +18 | +36 +18 | +28 +23 | +31 +23 | +34 +23 | +41 +23 | +33 +28 | +36 +28 | +39 +28 | +46 +28 |

| 18 | 30 | +8 +2 | +11 +2 | +15 +2 | +23 +2 | +14 +8 | +17 +8 | +21 +8 | +29 +8 | +21 +15 | +24 +15 | +28 +15 | +36 +15 | +28 +22 | +31 +22 | +35 +22 | +43 +22 | +34 +28 | +37 +28 | +41 +28 | +49 +28 | +41 +35 | +44 +35 | +48 +35 | +56 +35 |

| 30 | 50 | +9 +2 | +13 +2 | +18 +2 | +27 +2 | +16 +9 | +20 +9 | +25 +9 | +34 +9 | +24 +17 | +28 +17 | +33 +17 | +42 +17 | +33 +26 | +37 +26 | +42 +26 | +51 +26 | +41 +34 | +45 +34 | +50 +34 | +59 +34 | +50 +43 | +54 +43 | +59 +43 | +68 +43 |

| 50 | 65 | +10 +2 | +15 +2 | +21 +2 | +32 +2 | +19 +11 | +24 +11 | +30 +11 | +41 +11 | +28 +20 | +33 +20 | +39 +20 | +50 +20 | +40 +32 | +45 +32 | +51 +32 | +62 +32 | +49 +41 | +54 +41 | +60 +41 | +71 +41 | +61 +53 | +66 +53 | +72 +53 | +83 +53 |

| 65 | 80 | +51 +43 | +56 +43 | +62 +43 | +73 +43 | +67 +59 | +72 +59 | +78 +59 | +89 +59 | ||||||||||||||||

| 80 | 100 | +13 +3 | +18 +3 | +25 +3 | +38 +3 | +23 +13 | +28 +13 | +35 +13 | +48 +13 | +33 +23 | +38 +23 | +45 +23 | +58 +23 | +47 +37 | +52 +37 | +59 +37 | +72 +37 | +61 +51 | +66 +51 | +73 +51 | +86 +51 | +81 +71 | +86 +71 | +93 +71 | +106 +71 |

| 100 | 120 | +64 +54 | +69 +54 | +76 +54 | +89 +54 | +89 +79 | +94 +79 | +101 +79 | +114 +79 | ||||||||||||||||

| 120 | 140 | +15 +3 | +21 +3 | +28 +3 | +43 +3 | +27 +15 | +33 +15 | +40 +15 | +55 +15 | +39 +27 | +45 +27 | +52 +27 | +67 +27 | +55 +43 | +61 +43 | +68 +43 | +83 +43 | +75 +63 | +81 +63 | +88 +63 | +103 +63 | +104 +92 | +110 +92 | +117 +92 | +132 +92 |

| 140 | 160 | +77 +65 | +83 +65 | +90 +65 | +105 +65 | +112 +100 | +118 +100 | +125 +100 | +140 +100 | ||||||||||||||||

| 160 | 180 | +80 +68 | +86 +68 | +93 +68 | +108 +68 | +120 +108 | +126 +108 | +133 +108 | +148 +108 | ||||||||||||||||

| 180 | 200 | +18 +4 | +24 +4 | +33 +4 | +50 +4 | +31 +17 | +37 +17 | +46 +17 | +63 +17 | +45 +31 | +51 +31 | +60 +31 | +77 +31 | +64 +50 | +70 +50 | +79 +50 | +96 +50 | +91 +77 | +97 +77 | +106 +77 | +123 +77 | +136 +122 | +142 +122 | +151 +122 | +168 +122 |

| 200 | 225 | +94 +80 | +100 +80 | +109 +80 | +126 +80 | +144 +130 | +150 +130 | +159 +130 | +176 +130 | ||||||||||||||||

| 225 | 250 | +98 +84 | +104 +84 | +113 +84 | +130 +84 | +154 +140 | +160 +140 | +169 +140 | +186 +140 | ||||||||||||||||

| 250 | 280 | +20 +4 | +27 +4 | +36 +4 | +56 +4 | +36 +20 | +43 +20 | +52 +20 | +72 +20 | +50 +34 | +57 +34 | +66 +34 | +86 +34 | +72 +56 | +79 +56 | +88 +56 | +108 +56 | +110 +94 | +117 +94 | +126 +94 | +146 +94 | +174 +158 | +181 +158 | +190 +158 | +210 +158 |

| 280 | 315 | +114 +98 | +121 +98 | +130 +98 | +150 +98 | +186 +170 | +193 +170 | +202 +170 | +222 +170 | ||||||||||||||||

| 315 | 355 | +22 +4 | +29 +4 | +40 +4 | +61 +4 | +39 +21 | +46 +21 | +57 +21 | +78 +21 | +55 +37 | +62 +37 | +73 +37 | +94 +37 | +80 +62 | +87 +62 | +98 +62 | +119 +62 | +126 +108 | +133 +108 | +144 +108 | +165 +108 | +208 +190 | +215 +190 | +226 +190 | +247 +190 |

| 355 | 400 | +132 +114 | +139 +114 | +150 +114 | +171 +114 | +226 +208 | +233 +208 | +244 +208 | +265 +208 | ||||||||||||||||

| 400 | 450 | +25 +5 | +32 +5 | +45 +5 | +68 +5 | +43 +23 | +50 +23 | +63 +23 | +86 +23 | +60 +40 | +67 +40 | +80 +40 | +103 +40 | +88 +68 | +95 +68 | +108 +68 | +131 +68 | +146 +126 | +153 +126 | +166 +126 | +189 +126 | +252 +232 | +259 +232 | +272 +232 | +295 +232 |

| 450 | 500 | +152 +132 | +159 +132 | +172 +132 | +195 +132 | +272 +252 | +279 +252 | +292 +252 | +315 +252 | ||||||||||||||||

| Disclaimer: no rights can be derived from this information. Use of this information is at your own risk. | |||||||||||||||||||||||||

| Is the tolerance you are looking for not listed? This online calculator calculates all limit deviations. | |||||||||||||||||||||||||

© Mark Nauta

| largest and smallest limits in μm for shafts, tolerance grade t to zc | |||||||||||||||||||||||||

| nominal size in mm | t | u | v | x | y | z | za | zb | zc | ||||||||||||||||

| boven | t ⁄ m | 5 | 6 | 7 | 5 | 6 | 7 | 8 | 5 | 6 | 7 | 5 | 6 | 7 | 8 | 6 | 7 | 6 | 7 | 6 | 7 | 7 | 8 | 7 | 8 |

| 1 | 3 | - | - | - | +22 +18 | +24 +18 | +28 +18 | +32 +18 | - | - | - | +24 +20 | +26 +20 | +30 +20 | +34 +20 | - | - | +32 +26 | +36 +26 | +38 +32 | +42 +32 | +50 +40 | +54 +40 | +70 +60 | +74 +60 |

| 3 | 6 | - | - | - | +28 +23 | +31 +23 | +35 +23 | +41 +23 | - | - | - | +33 +28 | +36 +28 | +40 +28 | +46 +28 | - | - | +43 +35 | +47 +35 | +50 +42 | +54 +42 | +62 +50 | +68 +50 | +92 +80 | +98 +80 |

| 6 | 10 | - | - | - | +34 +28 | +37 +28 | +43 +28 | +50 +28 | - | - | - | +40 +34 | +43 +34 | +49 +34 | +56 +34 | - | - | +51 +42 | +57 +42 | +61 +52 | +67 +52 | +82 +67 | +89 +67 | +112 +97 | +119 +97 |

| 10 | 14 | - | - | - | +41 +33 | +44 +33 | +51 +33 | +60 +33 | - | - | - | +48 +40 | +51 +40 | +58 +40 | +67 +40 | - | - | +61 +50 | +68 +50 | ||||||

| 14 | 18 | - | - | - | +41 +33 | +44 +33 | +51 +33 | +60 +33 | +47 +39 | +50 +39 | +57 +39 | +53 +45 | +56 +45 | +63 +45 | +72 +45 | - | - | +71 +60 | +78 +60 | ||||||

| 18 | 24 | - | - | - | +50 +41 | +54 +41 | +62 +41 | +74 +41 | +56 +47 | +60 +47 | +68 +47 | +63 +54 | +67 +54 | +75 +54 | +87 +54 | +76 +63 | +84 +63 | +86 +73 | +94 +73 | ||||||

| 24 | 30 | +50 +41 | +54 +41 | +62 +41 | +57 +48 | +61 +48 | +69 +48 | +81 +48 | +64 +55 | +68 +55 | +76 +55 | +73 +64 | +77 +64 | +85 +64 | +97 +64 | +88 +75 | +96 +75 | +101 +88 | +109 +88 | ||||||

| 30 | 40 | +59 +48 | +64 +48 | +73 +48 | +71 +60 | +76 +60 | +85 +60 | +99 +60 | +79 +68 | +84 +68 | +93 +68 | +91 +80 | +96 +80 | +105 +80 | +119 +80 | +110 +94 | +119 +94 | +128 +112 | +137 +112 | ||||||

| 40 | 50 | +65 +54 | +70 +54 | +79 +54 | +81 +70 | +86 +70 | +95 +70 | +109 +70 | +92 +81 | +97 +81 | +106 +81 | +108 +97 | +113 +97 | +122 +97 | +136 +97 | +130 +114 | +139 +114 | +152 +136 | +161 +136 | ||||||

| 50 | 65 | +79 +66 | +85 +66 | +96 +66 | +100 +87 | +106 +87 | +117 +87 | +133 +87 | +115 +102 | +121 +102 | +132 +102 | +135 +122 | +141 +122 | +152 +122 | +168 +122 | +163 +144 | +174 +144 | +191 +172 | +202 +172 | ||||||

| 65 | 80 | +88 +75 | +94 +75 | +105 +75 | +115 +102 | +121 +102 | +132 +102 | +148 +102 | +133 +120 | +139 +120 | +150 +120 | +159 +146 | +165 +146 | +176 +146 | +192 +146 | +193 +174 | +204 +174 | +229 +210 | +240 +210 | ||||||

| 80 | 100 | +106 +91 | +113 +91 | +126 +91 | +139 +124 | +146 +124 | +159 +124 | +178 +124 | +161 +146 | +168 +146 | +181 +146 | +193 +178 | +200 +178 | +213 +178 | +232 +178 | +236 +214 | +249 +214 | +280 +258 | +293 +258 | ||||||

| 100 | 120 | +119 +104 | +126 +104 | +139 +104 | +159 +144 | +166 +144 | +179 +144 | +198 +144 | +187 +172 | +194 +172 | +207 +172 | +225 +210 | +232 +210 | +245 +210 | +264 +210 | +276 +254 | +289 +254 | +332 +310 | +345 +310 | ||||||

| 120 | 140 | +140 +122 | +147 +122 | +162 +122 | +188 +170 | +195 +170 | +210 +170 | +233 +170 | +220 +202 | +227 +202 | +242 +202 | +266 +248 | +273 +248 | +288 +248 | +311 +248 | +325 +300 | +340 +300 | +390 +365 | +405 +365 | ||||||

| 140 | 160 | +152 +134 | +159 +134 | +174 +134 | +208 +190 | +215 +190 | +230 +190 | +253 +190 | +246 +228 | +253 +228 | +268 +228 | +298 +280 | +305 +280 | +320 +280 | +343 +280 | +365 +340 | +380 +340 | +440 +415 | +455 +415 | ||||||

| 160 | 180 | +164 +146 | +171 +146 | +186 +146 | +228 +210 | +235 +210 | +250 +210 | +273 +210 | +270 +252 | +277 +252 | +292 +252 | +328 +310 | +335 +310 | +350 +310 | +373 +310 | +405 +380 | +420 +380 | +490 +465 | +505 +465 | ||||||

| 180 | 200 | +186 +166 | +195 +166 | +212 +166 | +256 +236 | +265 +236 | +282 +236 | +308 +284 | +304 +284 | +313 +284 | +330 +284 | +370 +350 | +379 +350 | +396 +350 | +422 +350 | +454 +425 | +471 +425 | +549 +520 | +566 +520 | ||||||

| 200 | 225 | +200 +180 | +209 +180 | +226 +180 | +278 +258 | +287 +258 | +304 +258 | +330 +258 | +330 +310 | +339 +310 | +356 +310 | +405 +385 | +414 +385 | +431 +385 | +457 +385 | +499 +470 | +516 +470 | +604 +575 | +621 +575 | ||||||

| 225 | 250 | +216 +196 | +225 +196 | +242 +196 | +304 +284 | +313 +284 | +330 +284 | +356 +284 | +360 +340 | +369 +340 | +386 +340 | +445 +425 | +454 +425 | +471 +425 | +497 +425 | +549 +520 | +566 +520 | +669 +640 | +686 +640 | ||||||

| 250 | 280 | +241 +218 | +250 +218 | +270 +218 | +338 +315 | +347 +315 | +367 +315 | +396 +315 | +408 +385 | +417 +385 | +437 +385 | +498 +475 | +507 +475 | +527 +475 | +556 +475 | +612 +580 | +632 +580 | +742 +710 | +762 +710 | ||||||

| 280 | 315 | +263 +240 | +272 +240 | +292 +240 | +373 +350 | +382 +350 | +402 +350 | +431 +350 | +448 +425 | +457 +425 | +477 +425 | +548 +525 | +557 +525 | +577 +525 | +606 +525 | +682 +650 | +702 +650 | +822 +790 | +842 +790 | ||||||

| 315 | 355 | +293 +268 | +304 +268 | +325 +268 | +415 +390 | +426 +390 | +447 +390 | +479 +390 | +500 +475 | +511 +475 | +532 +475 | +615 +590 | +626 +590 | +647 +590 | +679 +590 | +766 +730 | +787 +730 | +936 +900 | +957 +900 | ||||||

| 355 | 400 | +319 +294 | +330 +294 | +351 +294 | +460 +435 | +471 +435 | +492 +435 | +524 +435 | +555 +530 | +566 +530 | +587 +530 | +685 +660 | +696 +660 | +717 +660 | +749 +660 | +856 +820 | +877 +820 | +1036 +1000 | +1057 +1000 | ||||||

| 400 | 450 | +357 +330 | +370 +330 | +393 +330 | +517 +490 | +530 +490 | +553 +490 | +587 +490 | +622 +595 | +635 +595 | +658 +595 | +767 +740 | +780 +740 | +803 +740 | +837 +740 | +960 +920 | +983 +920 | +1140 +1100 | +1163 +1100 | ||||||

| 450 | 500 | +387 +360 | +400 +360 | +423 +360 | +567 +540 | +580 +540 | +603 +540 | +637 +540 | +687 +660 | +700 +660 | +723 +660 | +847 +820 | +860 +820 | +883 +820 | +917 +820 | +1040 +1000 | +1063 +1000 | +1290 +1250 | +1313 +1250 | ||||||

| Disclaimer: no rights can be derived from this information. Use of this information is at your own risk. | |||||||||||||||||||||||||

| Is the tolerance you are looking for not listed? This online calculator calculates all limit deviations. | |||||||||||||||||||||||||

© Mark Nauta

1. Introduction

2. Limits

2.1 Fundamental deviation

2.2 Tolerance grade

2.3 ?

2.4 Calculation of limits

2.5 Check of limits

3. Fit

3.1 Introduction

3.2

3.3 Shaft- and hole-basis fit

4. Glossary

© Mark Nauta

To address this variation, designers define acceptable limits, known as tolerances, which indicate how much deviation is permissible ("tolerate" meaning "allow").

When a designer selects a narrow tolerance range, more parts will fall outside these limits due to inherent variations. Consequently, a greater number of parts will be rejected, leading to higher costs per approved part. The inverse relationship also holds true: increasing tolerance leads to fewer failures and lower costs.. Besides the fact that not every product has to be the same, the big advantage of fits is that it helps with the interchangeability of parts.

Besides the fact that not every product has to be the same, the big advantage of fits is that it helps with the interchangeability of parts.© Mark Nauta

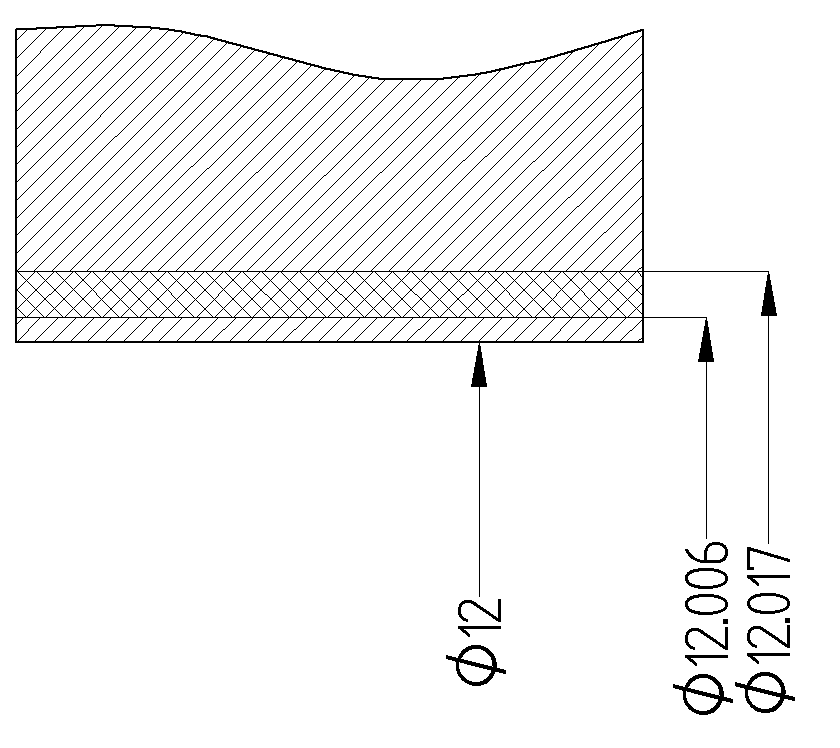

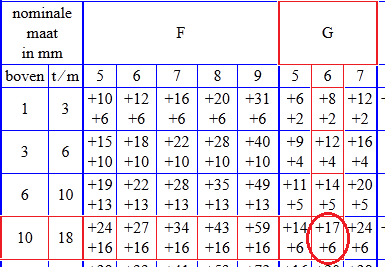

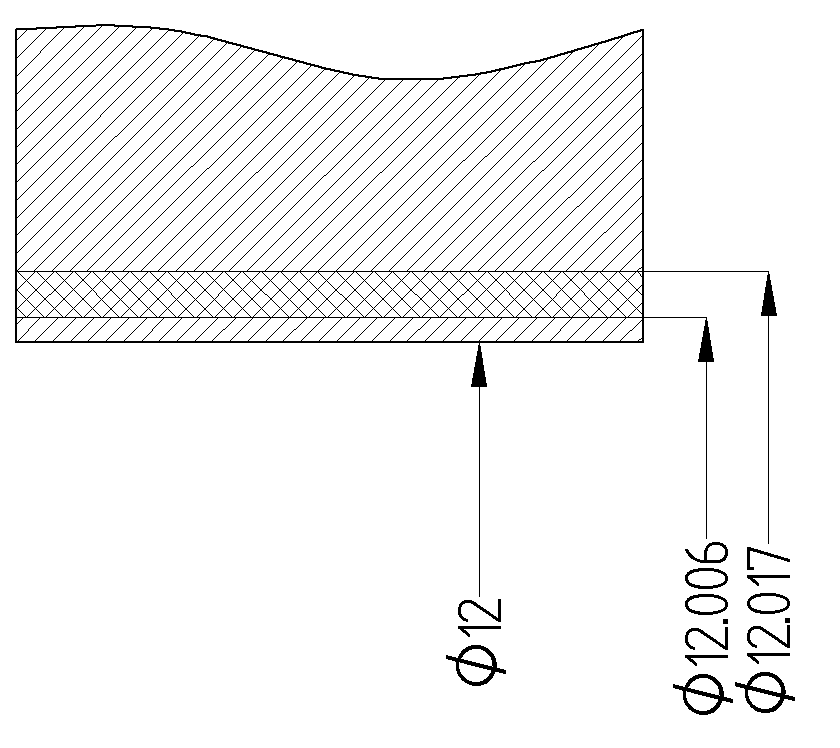

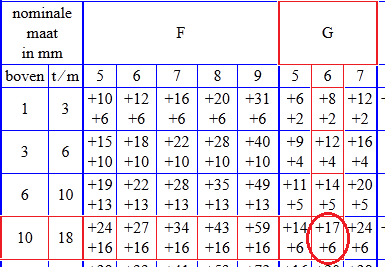

Example: '12 G6': nominal size = '12'; fundamental deviation identifier = 'G'; tolerance grade = '6'.

The limits can be looked up in the tables above:

• the fundamental deviation identifier 'G' shows that table 'holes, F to H' is applicable.

• in this table, the left two columns show that for a nominal size of 12, group 'above 10, to 18' is applicable.

• in this group, the upper and lower limit of G6 can be read: '+6' en '+17' (μm) resp.

>>> thus, the limits of '12 G6' are 12.006 en 12.017 .

The fundamental deviation and tolerance grade will be discussed in the next paragraphs.

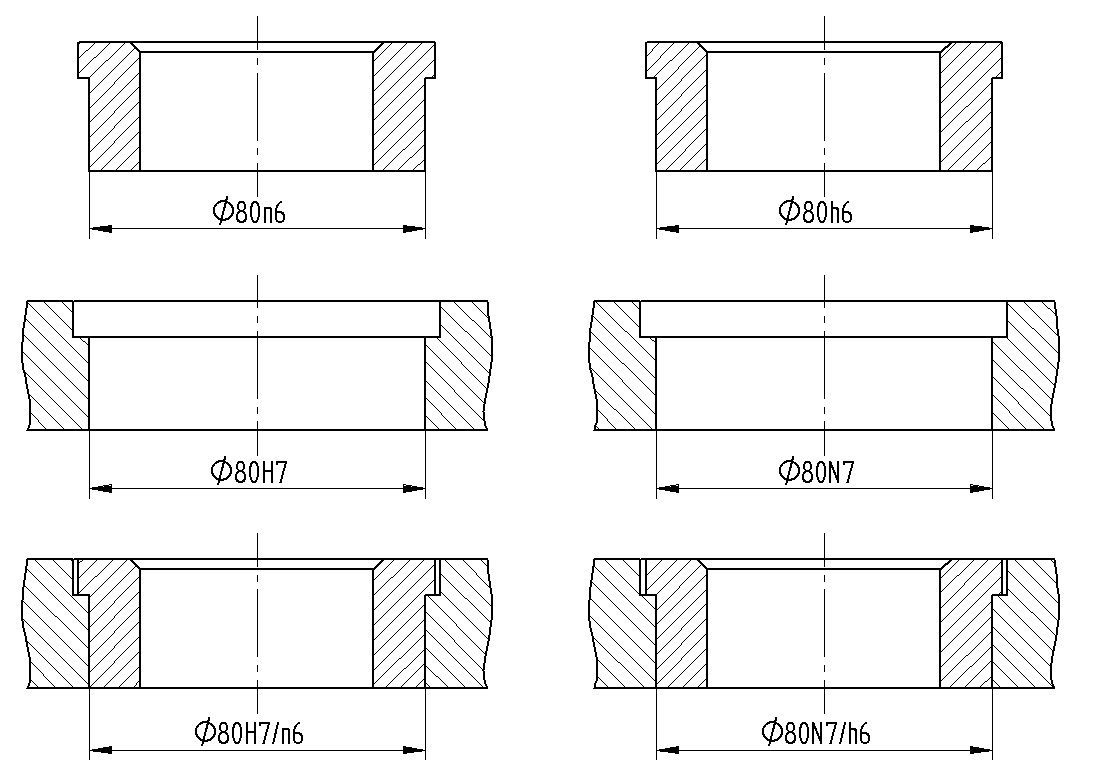

As explained above, the Fundamental deviation determines:

- the lower limit

- the direction of the deviation

On a drawing, the Fundamental deviation is indicated by means of a character:

- a lower case letter for an inner limit ("shaft"), or

- an upper case letter for an outer limit ("hole")

In the norm the actual values are documented; the table below is shortened and copied from the norm:

| Fundamental deviation (-indicator) in μm | |||||||||||||

| nominal size | Indicator | ||||||||||||

| above | to | A | B | C | ... | G | H | ... | M | ... | P | ... | Z |

| 1 | 3 | +270 | +140 | +60 | ... | +2 | 0 | ... | -2 | ... | -6 | ... | -26 |

| 3 | 6 | +270 | +140 | +70 | ... | +4 | 0 | ... | -4 | ... | -12 | ... | -35 |

| 6 | 10 | +280 | +150 | +80 | ... | +5 | 0 | ... | -6 | ... | -15 | ... | -42 |

| 10 | 14 | +290 | +150 | +95 | ... | +6 | 0 | ... | -7 | ... | -18 | ... | -50 |

| ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... |

| 355 | 400 | +1350 | +680 | +400 | ... | +18 | 0 | ... | -21 | ... | -62 | ... | -1000 |

| 400 | 450 | +1500 | +740 | +440 | ... | +20 | 0 | ... | -23 | ... | -68 | ... | -1100 |

| 450 | 500 | +1650 | +840 | +480 | ... | +20 | 0 | ... | -23 | ... | -68 | ... | -1250 |

It is noticeable from this table that the size deviation depends on the size of the nominal size, namely: "the larger the product, the greater the size deviation".

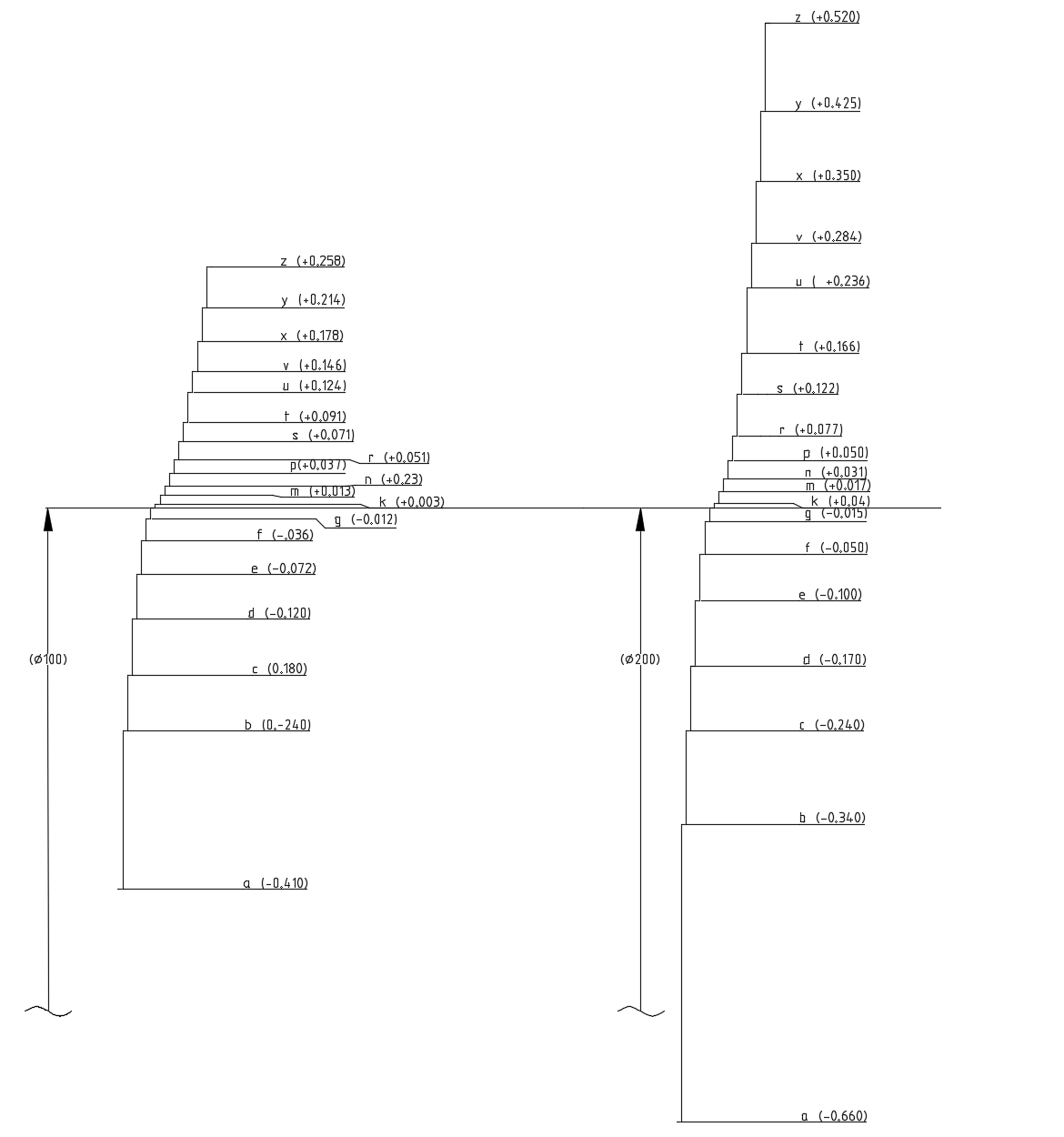

The figure below shows this graphically. It shows the Fundamental deviations of two shafts (∅100mm and ∅200mm respectively).

The tolerance grade determines the 'width' of the allowed deviation

On drawing this is indicated by a number, in the previous example '12 G6' this is '6'.

A lower number means more accurate, a higher number less accurate:

• 1-4: very accurate

• 5-11: accurate and plain

• 12-16: rough

The (shortened) table below is taken from the norm:

| tolerance in μm | |||||||||||||

| nominal size | Tolerance grade IT | ||||||||||||

| above | to | 01 | 0 | 1 | 2 | 3 | ... | 6 | 7 | 8 | .... | 15 | 16 |

| 1 | 3 | 0.3 | 0.5 | 0.8 | 1.2 | 3 | ... | 6 | 10 | 14 | .... | 400 | 600 |

| 3 | 6 | 0.4 | 0.6 | 1 | 1.5 | 3 | ... | 8 | 12 | 18 | .... | 480 | 750 |

| 6 | 10 | 0.4 | 0.6 | 1 | 1.5 | 3 | ... | 9 | 15 | 22 | .... | 580 | 900 |

| 10 | 18 | 0.5 | 0.8 | 1.2 | 2 | 3 | ... | 11 | 18 | 27 | .... | 700 | 1100 |

| ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... |

| 250 | 315 | 2.5 | 4 | 6 | 8 | 3 | ... | 32 | 52 | 81 | .... | 2100 | 3200 |

| 315 | 400 | 3 | 5 | 7 | 9 | 3 | ... | 36 | 57 | 89 | .... | 2300 | 3600 |

| 400 | 500 | 4 | 6 | 8 | 10 | 3 | ... | 40 | 63 | 97 | .... | 2500 | 4000 |

It is noticeable from this table that the tolerance depends on the the nominal size, in this way: "the larger the product, the greater the tolerance". And this corresponds to the intuitive feeling that something larger can be made less precise.

In fact, the tolerance class is the accuracy of the machining operation, and therefore largely determines the type of machining.

The table below indicates which operation can be used to achieve a certain tolerance:

| Machine operation vs. Tolerance grade | |||||||||||||||

| IT grade | |||||||||||||||

| ↓operation | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| lapping | + | + | + | + | |||||||||||

| honing | + | + | + | ||||||||||||

| super finish | + | + | + | ||||||||||||

| cylindrical grinding | + | + | + | + | |||||||||||

| diamond turning | + | + | + | + | |||||||||||

| surface grinding | + | + | + | + | + | ||||||||||

| broaching | + | + | + | + | + | ||||||||||

| reaming | + | + | + | + | + | ||||||||||

| turning, boring | + | + | + | + | + | + | + | ||||||||

| sawing | + | + | + | ||||||||||||

| milling | + | + | + | + | + | ||||||||||

| extruding | + | + | + | + | |||||||||||

| boring | + | + | + | + | |||||||||||

| injection molding | + | + | + | + | |||||||||||

| forging | + | + | + | + | |||||||||||

| die casting | + | + | + | ||||||||||||

| rolling, cutting | + | + | + | ||||||||||||

In summary, the limits are determined by the combination of the Fundamental deviation, and tolerance grade:

• Fundamental deviation: determines the lower limit, and direction (positive/negative/symmetric

• tolerance grade: determines the magnitude of the tolerance

• the absolute (lower- and upper-) limits are dependent on the nominal size

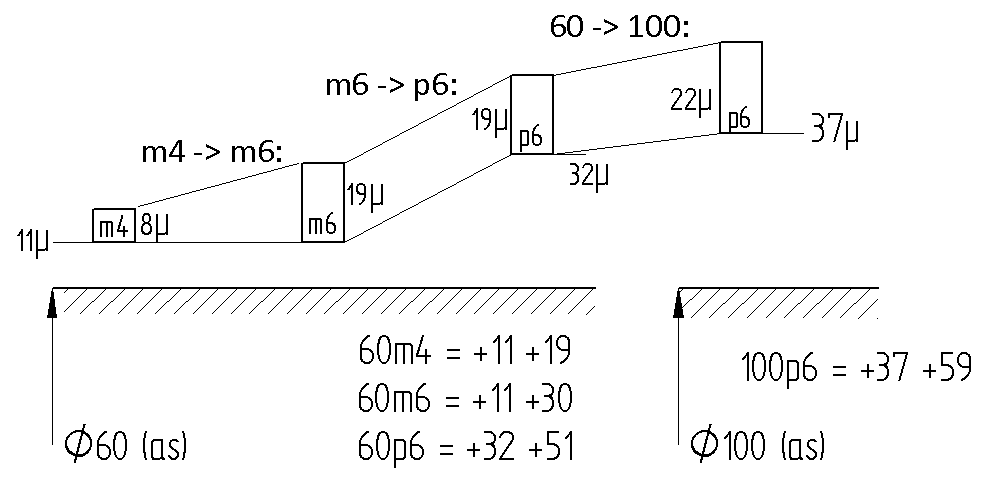

The picture below can make this clear (tip: 'read' from left to right):

When te nominal size, fundamental deviation, and tolerance grade are known, the limits can be lookep up.

As an example: '10 P8'

a. search in the table above: row 'size group 6 tp 10', column 'P' >>>fundamentall deviation -15 μm

b. search in the table above: row 'size group 6 to 10', column '8' >>>tolerace 22 μm

c. >>> limits -15 μm and (-15-22=) -37 μm, which evaluates to 9.985 to 9.963 mm

For this specific example, the limits can be directly looked up in the table(s) with most used limits: : see table.

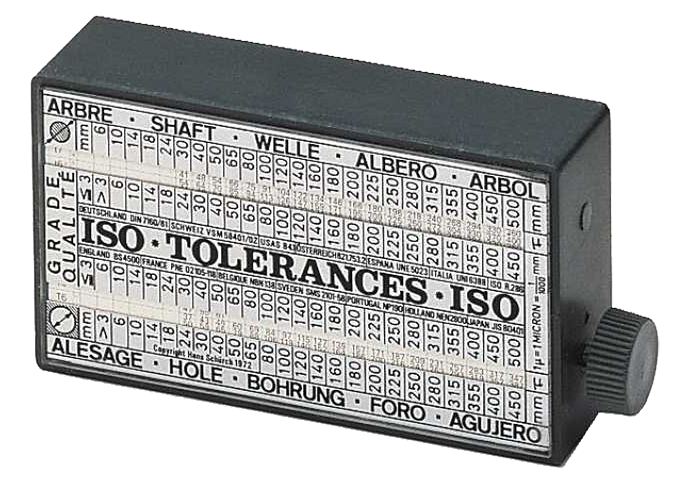

Another way to lookup the limits is by meands of a 'Tolerator', this is a handy tool to find the most used limits, by turning a knob.

To verify if the feature fits the limits can be achieved with measurement tools like calipers. There are also check tools specifically for tolerances: gauges. With a gauge it can be quickly checked whether the dimensions are correct: 'right or wrong'.

Properties of a gauge:

• a gauge is feature-specific, so it is suitable for one application, eg 'hole'.

• a gauge is also size-related, so it is suitable for one tolerance, e.g. '20 H7'.

The gauge has an approval and rejection side. The reject side can usually be recognized by a red mark.

Examples of gauges:

The use is quite simple. Both sides of the gauge should be tested. The feature does not meet the limits if:

• the gauge does not fit on the approval side (the shape is too small); or:

• the gauge does fit on the rejection side (then the shape is too large)

The advantages and disadvantages of gauges follow from their properties:

Advantages: fast, easy to use, little can go wrong, also checks for shape deviations (e.g. roundness of a hole)

Disadvantages: expensive to purchase, shape and size dependent so large sets are required, must be periodically calibrated, actual dimensions of the shape to be checked are unknown

© Mark Nauta

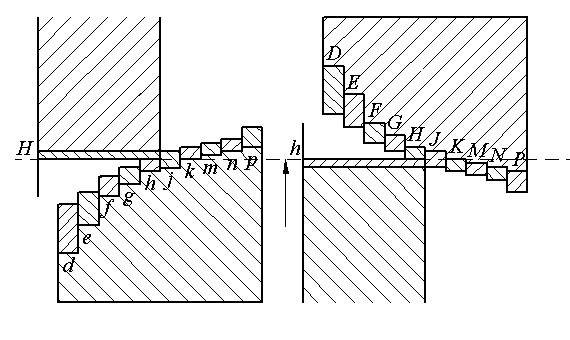

When combining a shaft and a hole, automatically the question arises: will it fit ?

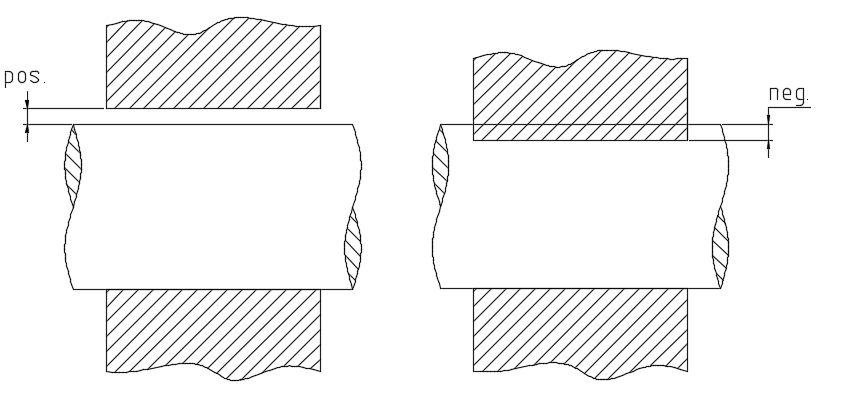

The nature of the fit is determined by the clearance between the shaft and the hole: with a positive clearance the shaft is smaller than the hole, and with a negative clearance the shaft is larger than the hole.

If the maximum limit of a shaft is smaller than the minimum limit of a hole, it is referred to as a clearance fit.

If the minimum limit of a shaft is larger than the maximum limit of a hole, it is referred to as a transition fit.

If there is a potential positive or negative clearance, it is referred to as an interference fit.

Depending on the application, a specific type of fit is chosen.

For a sliding application, for example a piston-cylinder combination, a clearance fit will be chosen.

If the parts need to remain in place, but can still be removed afterwards, for example a bearing in a bearing housing, then a transition fit will be chosen.

If the parts must be inextricably connected to each other, and even be able to transmit/resist forces, an interference fit will be chosen.

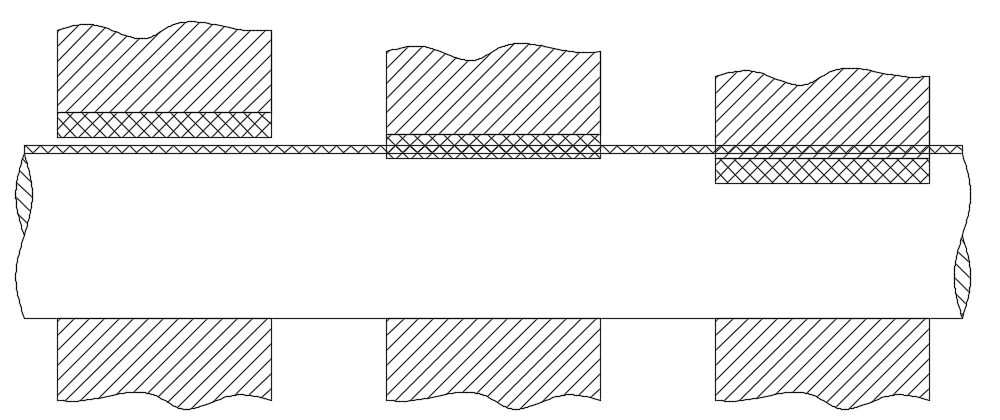

In theory, it is possible to conceive of any imaginable (exotic) fit, but in practice, this is undesirable and even unnecessary. Unnecessary because a limited number of combinations of shafts and holes have proven sufficient for the majority of structural problems. Undesirable because anyone applying a fit tends to rely on established principles.

The most commonly used fits, or combinations of shaft and hole tolerances, are referred to as preferred fits.

The table below provides an overview of preferred fits. Please note that preferred fits apparently remain independent (!) of the nominal size:

| clearance fit | ||||||

| shaft- basis fit | h5 | h6 | h7 | (h8) | h9 | h11 |

| G6-H6 | F7-G7-H7 | E8-F8-G8-H8 | D9-E9-F9-H9 | D10-E10-F10-H10 | B11-C11-D11-E11-F11-H11 | |

| hole- basis- fit | H6 | H7 | H8 | (H9) | (H10) | H11 |

| g5-h5 | f6-g6-h6 | e7-f7-g7-h7 | d8-e8-f8-h8 | d9-e9-f9-h9 | b11-c11-d11-e11-f11-h11 | |

| transitional fit | |||

| shaft- basis fit | h5 | h6 | h7 |

| J6-K6-M6-N6 | J7-K7-M7-N7 | J8-K8-M8-N8 | |

| hole- basis- fit | H6 | H7 | H8 |

| j5-k5-m5-n5 | j6-k6-m6-n6 | j7-k7-m7-n7 | |

| interference fit | |||

| shaft- basis fit | h5 | h6 | h7 |

| P6-R6-S6-T6 | P7-R7-S7-T7-U7 | R8-T8-U8 | |

| hole- basis- fit | H6 | H7 | H8 |

| p5-r5-s5-t5 | p6-r6-s6-t6-u6 | s7-t7-u7 | |

From the table above can be read that combination h7-F8 is a prevailed, clearance fit.

Elaborate:

• find shaft '52 h7' in table: limits 51,970 en 52,000

• find hole '52 F8' in table: limits 52,030 en 52,076

So in this case, it is a clearance fit, met minimum play +0,030 and maximum play +0,106 (mm)

('smallest possible hole minus largest possible shaft' resp. 'larget posible hole minus smallest possible shaft')

The table above mentions 'hole-basis fit' and 'shaft-basis fit', these are preferred fits where the fundamental deviation of the hole (resp. shaft) is zero. The counterpart can be 'freely' chosen.

| Type of fit | shaft-basit fit | hole-basis fit | application example |

| clearance fits | H6/h5 | H6/h5 | gear on shaft |

| G7/h6 | H7/g6 | piston and cylinder | |

| F8/h7 | H8/f7 | machine tool spindles regulator bearings sliding rods | |

| D10/h9 | H10/d9 | bearings in agricultural machines | |

| C11/h11 | H11/c11 | pivots latches | |

| transitional fits | J7/h6 K7/h6 N7/h6 | H7/j6 H7/k6 H7/n6 | retaining rings easy dismountable bearings |

| J8/h7 | H8/j7 | frequently removed bearing bushes | |

| interference fits | P7/h6 S7/h6 | H7/p6 H7/s6 | seated bearing bushes parts without retaining |

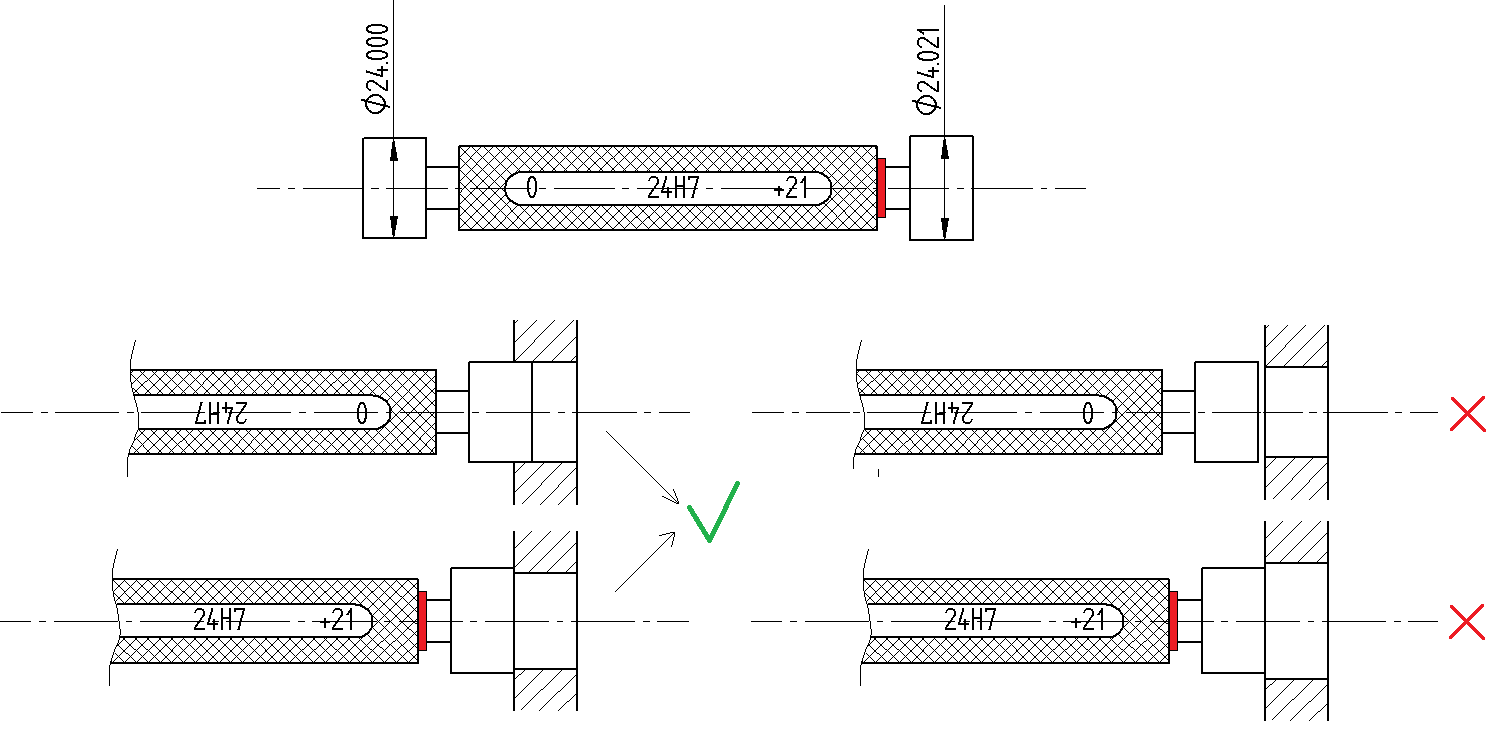

The picture below gives a graphical representation:

Example of a transitional fit: '20 H7/k6' in other words a combination of a hole 20 H7 with shaft 20 k6.

Elaboration:

• look up hole '20 H7' in the table: limit sizes 20.000 and 20.021

• look up shaft '20 k6' in the table: limit sizes 20.002 and 20.015

Therefore it is a transitional fit, with minimum clearance -0.015 and maximum clearance +0.019 (mm)

© Mark Nauta

| Remark: where is stated 'shaft', is also meant 'inner limits'; where stated 'hole', is also meant 'outer limits' | ||

| terminology | description | explanation |

| Basic size, Nominal size | the perfect size of a designed feature | link |

| Fit | play between a hole and a shaft | link |

| Clearance fit | fit where the largest deviation of the hole will always fit he smallest deviation of the shaft | link |

| Interference fit | fit where the smallest deviation of the hole will never fit he largest deviation of the shaft | link |

| Transition fit | fit with a possible or negative play | link |

| Play | difference between the actual inner- and outer size | link |

| Minimum, maximum limits, Limits of size | extreme permissible sizes of a feature | link |

| Tolerance | spread between the largest and smallest limits of size | link |

| Tolerance interval | the zone between lower- and upper limit of size | link |

| Deviation | actual value minus its nominal size | link |

| Fundamental deviation (-identifier) | the lower limit deviation (=lying closest to the nominal size). On drawing, this is denoted by a lower case letter for a shaft, or an upper case letter for a hole | link |

| Tolerance direction | direction of the tolerance wrt. the nominal size, can be either ('larger') or negative ('smaller') of symmetric | link |

| Tolerance grade (-number) | a characteristic of the accuracy of the operation | link |

| Gauge | tool to determine (dis-)approval. A gauge is applicable for one shape and one tolerance | link |

| Shaft-basis fit | fit (combination of shaft and hole), where the fundamental deviation of the shaft is zero (in short: 'h'); counterpart (hole) differs | link |

| Hole-basis fit | fit (combination of shaft and hole), where the fundamental deviation of the hole is zero (in short: 'H'); counterpart (shaft) differs | link |

© Mark Nauta